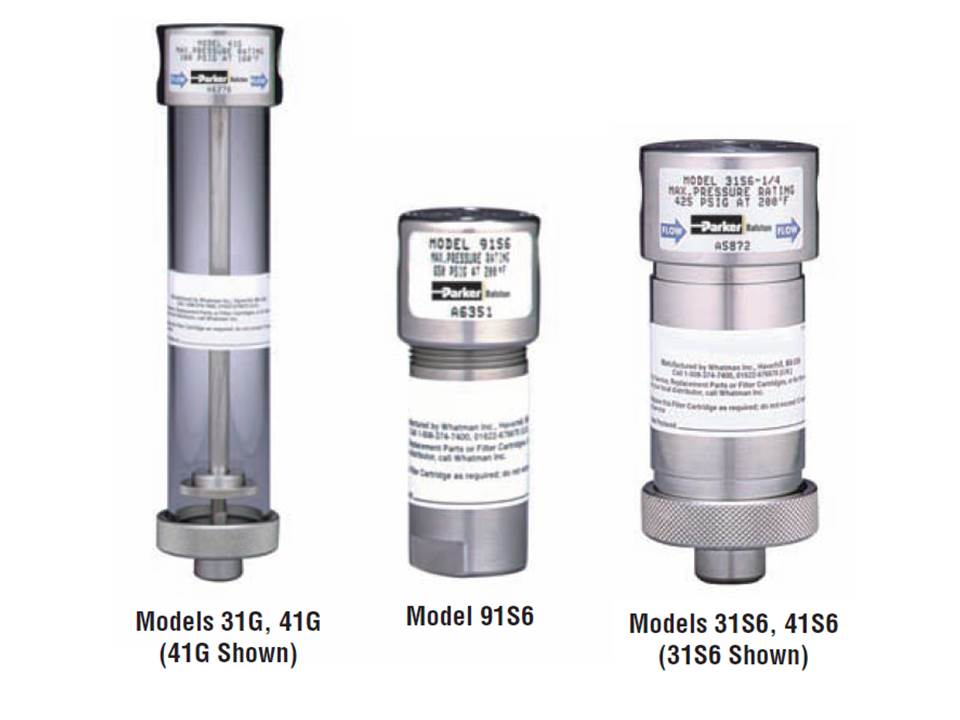

Category: Sample Filters

Product Code: Coalescer Membrane Combination Filters

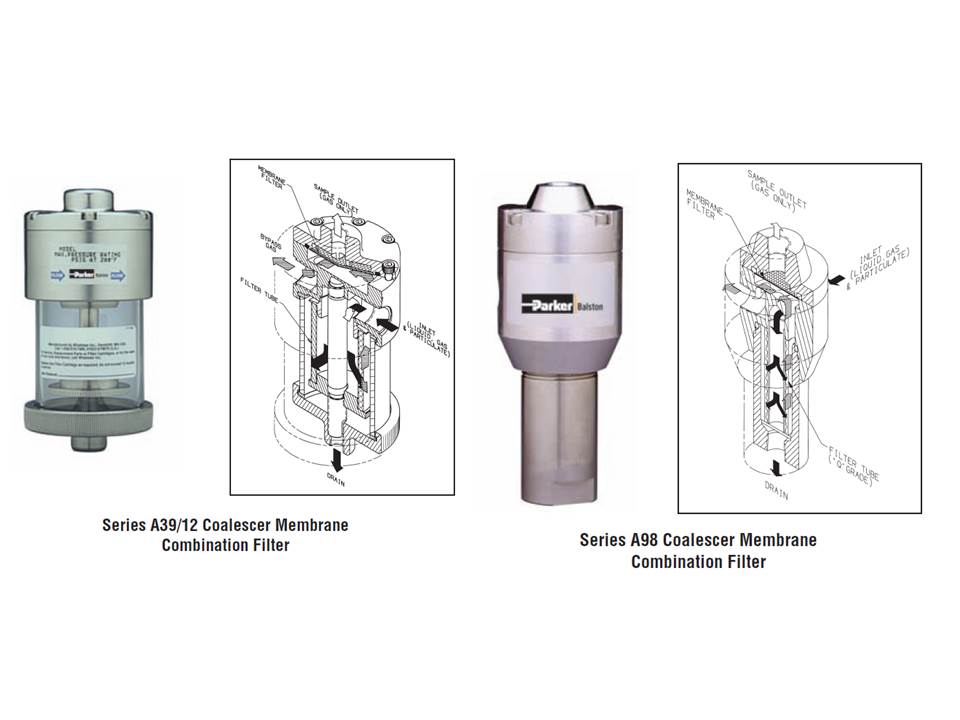

Series A98 Coalescer Membrane Combination Filters

A98 Series offers continuous coalescing of all liquid and the security of hydrophobic membrane protection all in one unit

Fewer fittings required - reducing risk of leaks

More compact - no need for separate coalescers

Less maintenance and downtime as the membrane is fully protected from solids & liquids

Series A98 Coalescer Membrane Combination Filter

The Balston Coalescer Membrane Combination Filter is designed to remove entrained liquid and particulate in gas samples for a wide variety of applications, and thereby prevents contamination or damage to the analyzers and sample system components. Typically located upstream from the analyzer or component it is protecting, the Coalescer Membrane Combination provides protection even if other sample system components fail.

The Coalescer Membrane Combination offers the performance and protection of the 98 Series Membrane Filter with the additional benefits of coalescing liquids and entrapment of particulates, offering maximum protection of the membrane. There is no need for prefiltration which places more volume in the sample system, and requires more space for installation and more potential for leaks.

The Series A98 consists of a housing with a porous membrane filter, which is supported by a sintered porous disk located on the “outlet” side of the housing. Gas enters through the “inlet” port and is directed down through the coalescing filter. The coalescer traps all particulates and continuously drains liquid contaminants. The sample gas then flows upward to the upstream side of the membrane, and exits from the “outlet” port on the downstream side. Entrained liquid will not flow through the membrane, and will exit through the drain port on the downstream side of the coalescer.

The Membrane

Microscopic pores contained within the membrane permit molecules of gas or vapor to flow through easily, allowing the composition of the sample gas to remain unchanged. Even the smallest liquid molecules remain trapped and are unable to flow through the membrane’s small passages under normal operating conditions. This is due to the high surface tension which causes liquid molecules to bind tightly together to form a group of molecules, moving together, which is too large to fit through the pores of the membrane.

The membrane is extremely inert, and is recommended for most process liquid applications, with the exception of hydrofluoric acid. It is also recommended for use in systems designed for PPB, PPM, and “percent level” component concentrations, as a result of its very low absorption characteristics. The membrane is strong and durable, but also very soft and pliable.

A39/12 Series Coalescer: Membrane Combination Filter

The A39/12 Series offers continuous coalescing of all liquid and the security of hydrophobic membrane protection all in one unit

Fewer fittings required - reducing risk of leaks

More compact - no need for separate coalescers

Less maintenance and downtime as the membrane is fully protected fromsolids & liquids

Series A39/12 Coalescer Membrane Combination Filter

The Balston Coalescer Membrane Combination Filter is designed to remove entrained liquid and particulate in gas samples for a wide variety of applications, and thereby prevents contamination or damage to the analyzers and sample system components. Typically located upstream from the analyzer or component it is protecting, the Coalescer Membrane Combination provides protection even if other sample system components fail.

The Coalescer Membrane Combination offers the performance and protection of the A39/12 Series Membrane Filter with the additional benefits of coalescing liquids and entrapment of particulates, offering maximum protection of the membrane. There is no need for prefiltration which places more volume in the sample system, and requires more space for installation and more potential for leaks.

The A39/12 Series consists of a housing with a porous membrane filter, which is supported by a sintered porous disk located on the “outlet” side of the housing. Gas enters through the “inlet” port and is directed down through the coalescing filter. The coalesce traps all particulates and continuously drains liquid contaminants. The sample gas then flows upward to the upstream side of the membrane, and exits from the “outlet” port on the downstream side. Entrained liquid will not flow through the membrane, and will exit through the drain port on the downstream side of the coalescer.

The Membrane

Microscopic pores contained within the membrane permit molecules of gas or vapor to flow through easily, allowing the composition of the sample gas to remain unchanged. Even the smallest liquid molecules remain trapped and are unable to flow through the membrane’s small passages under normal operating conditions. This is due to the high surface tension which causes liquid molecules to bind tightly together to form a group of molecules, moving together, which is too large to fit through the pores of the membrane.

The membrane is extremely inert, and is recommended for most process liquid applications, with the exception of hydrofluoric acid. It is also recommended for use in systems designed for PPB, PPM, and “percent level” component concentrations, as a result of its very low absorption characteristics. The membrane is strong and durable, but also very soft and pliable.

Add to Enquiry Cart

Add to Enquiry Cart Print

Print